Main advantages

Fully automated splitting operation, including loading and palletizing

Splitting machine with both the loading and unloading conveyor

Splitting of the entire palette layer

With side teeth and hydraulic shock for higher product quality

Optional programming and setting of required parameters

Optional interconnection with a robot and online interconnection with a concreting plant

Description

Products

Split wall blocks, Split palisades, Split face post blocks

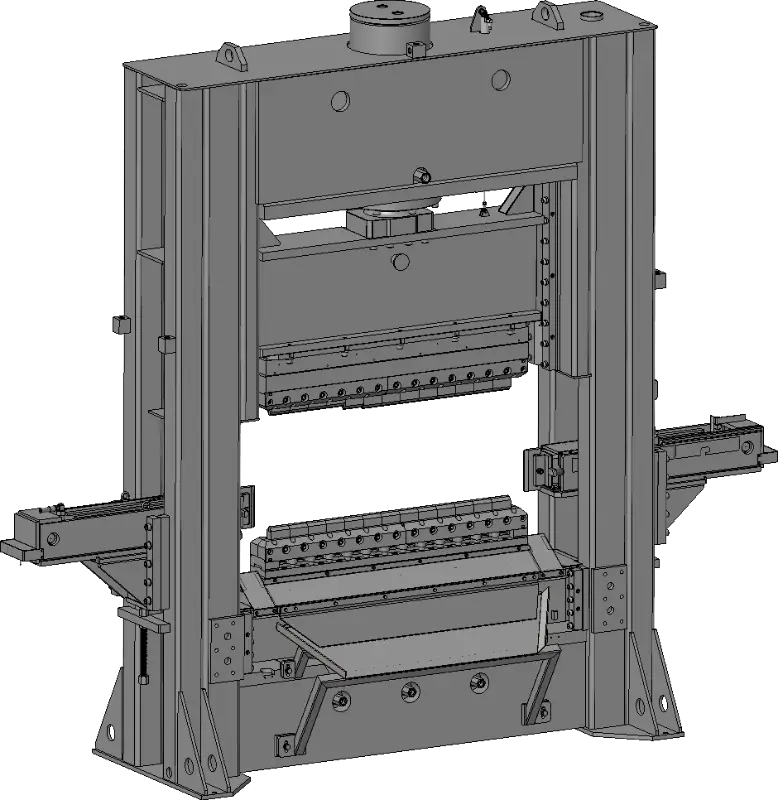

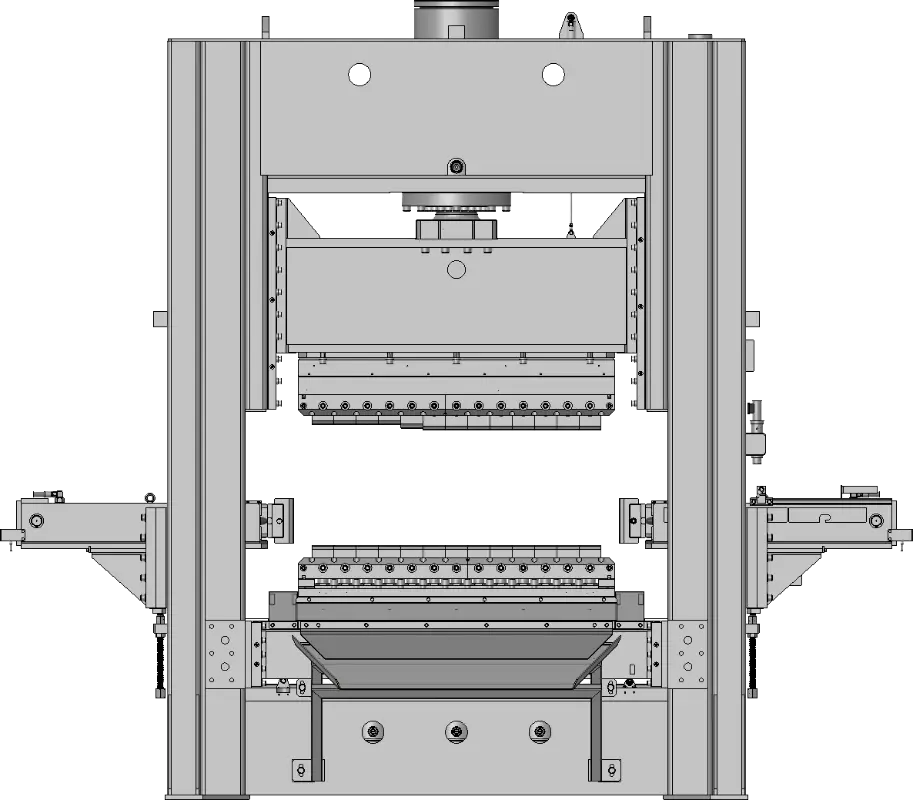

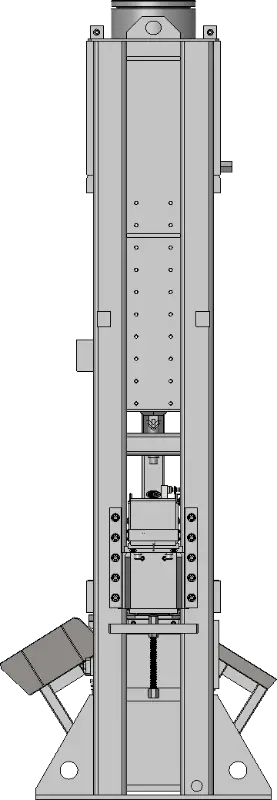

Machine description

Palette layer loading

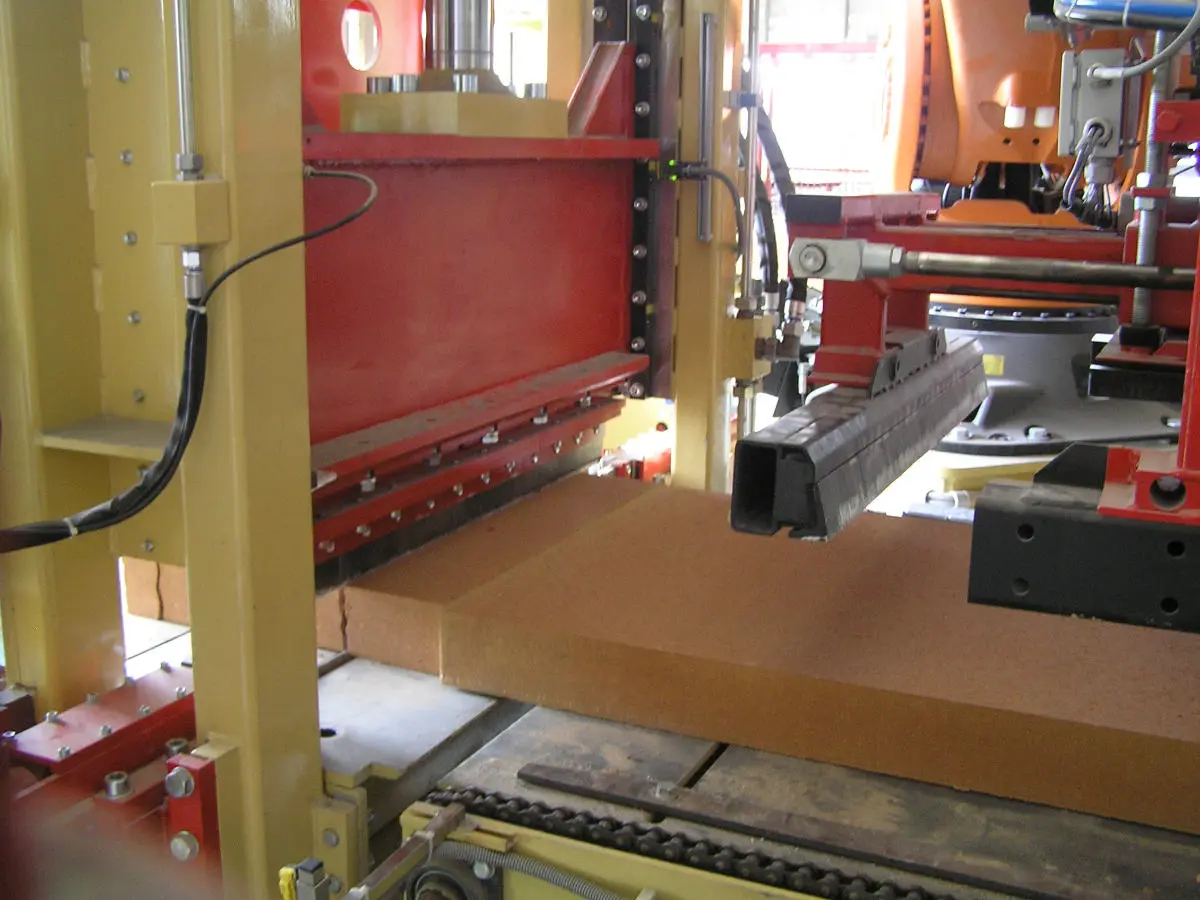

Combining a unique manipulator, an optimally long conveyor and a splitter equipped with a special hydraulic system, you can achieve unrivalled production performance and a significant reduction in operating costs. The splitters are designed to process regular or irregular stone as efficiently as possible. They can process up to 50 - 60 tons per shift. A special hydraulic system with cooling unit, used exclusively by Gestra, gives the splitters high performance and the ability to split even the hardest stones.

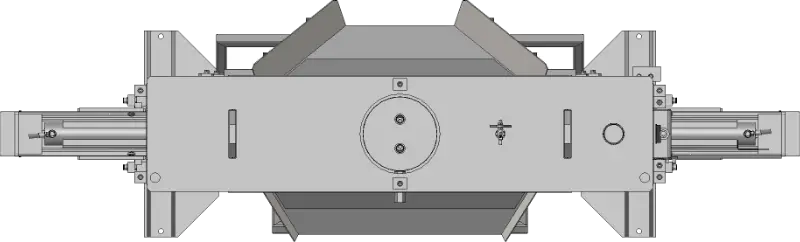

Turn table

The unrivalled features of the MK manipulator ensure easier handling of the stone blocks. It can be used to move long stones and place them precisely under the splitting head, and once a piece of stone has been split off, it can be turned and tilted in all directions.

Push plate

A conveyor with special chains is attached to the splitting table of the splitter, which descends with the table when splitting. This design allows the splitting of long stones without the risk of damaging the table or the conveyor, the splitting takes place only between the teeth and thus increases the quality of the split surface. The stone does not "wobble" on the table during splitting. The robust construction of the conveyor guarantees a long service life. The floating knives that adapt to the shape of the stone also help to increase the quality of the split surface.

Chain rod conveyor

Both the upper and lower tool is leveling, which results in better quality of split products. We use strong teeth in the tools, which have a long service life.

Splitting system

The machine has a control panel with joysticks that control the manipulator and conveyors. The manipulator not only increases the productivity of the machine, but eliminates the physically very demanding work of precisely placing the stone under the splitting head and greatly increases the safety when working on the machine.

Moving table for waste

The reverse time of the upper tool can be adjusted so that it does not travel unnecessarily to the end position when splitting smaller products and thus slow down production unnecessarily.

Palettizing

The splitter and conveyors are extra robust to minimize repair time and unproductive machine maintenance. The conveyors have heavy chains and thick links with reinforcement. The splitter head has a solid construction of all components to withstand long term splitting loads of up to 180 t.

Quality components are also used in the hydraulic power pack where it is not visible at first glance, but it has a major impact on the performance, reliability and life of the machine. The heart of the machine is the radial cast iron pump, which ensures a gradual increase in pressure and a smooth build-up of pressure in the stone, which increases the quality of the splitting.

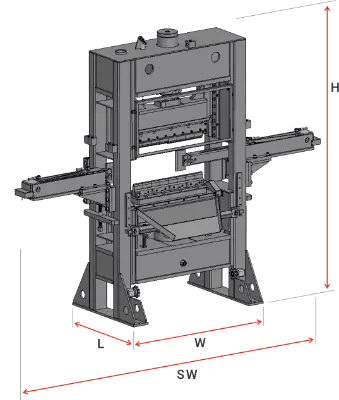

Technical parameters

HSB 600 series

| metric units | imperial units | |

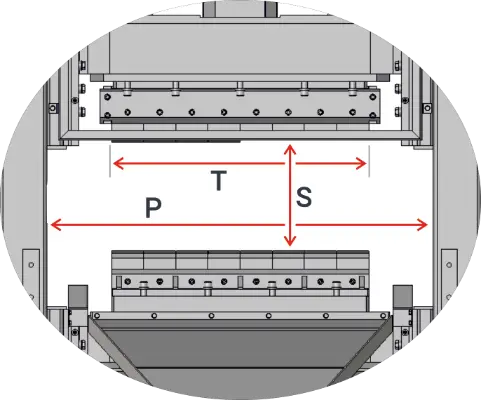

| Tool length (T): | 600 mm | ~ 23 ²/₃" |

| Stroke (S): | 280 mm | ~ 11" |

| Splitting power: | 43 / 53 tons | ~ 47 / 58 US tons |

| Quantity of splitting teeth: | 12+12 (with 50 mm) / 6+6 (width 100 mm) pcs | 12+12 (with 2") / 6+6 (width 4") pcs |

| Main dimensions | ||

| Width (W): | 1 260 mm | ~ 4ʹ 1 ²/₃" |

| Width - side tools extended (SW): | 1 935 mm | ~ 6ʹ 4 ¹/₅" |

| Length (L): | 730 mm | ~ 2ʹ 4 ³/₄" |

| Height (H): | 2 350 mm | ~ 7ʹ 8 ¹/₂" |

| Weight (without oil filling): | ~ 2 400 kg | ~ 5 295 lbs |

| Hydraulic unit | ||

| Nominal pressure: | 300 bar | ~ 4 350 psi |

| Oil tank filling: | 200 l | ~ 53 gal |

| Electrical system | 3NPE AC 50 Hz 230/400 V | 3NPE AC 60 Hz 275/480 V |

| Main motor: | 7,5 kW | ~ 10 HP |

| Cooling unit: | 0,75 kW | ~ 1 HP |

| Heating coil: | 1,5 kW | ~ 2 HP |

HSB 800 series

| metric units | imperial units | |

| Tool length (T): | 800 mm | ~ 31 ¹/₂" |

| Stroke (S): | 280 mm | ~ 11" |

| Splitting power: | 43 / 53 / 63 / 80 tons | ~ 47 / 58 / 70 / 88 US tons |

| Quantity of splitting teeth: | 16+16 (with 50 mm) / 8+8 (width 100 mm) pcs | 16+16 (with 2") / 8+8 (width 4") pcs |

| Main dimensions | ||

| Width (W): | 1 810 mm | ~ 5ʹ 11 ¹/₄" |

| Width - side tools extended (SW): | 2 265 mm | ~ 7ʹ 5 ¹/₅" |

| Length (L): | 750 mm | ~ 2ʹ 5 ¹/₂" |

| Height (H): | 2 565 mm | ~ 8ʹ 5" |

| Weight (without oil filling): | ~ 4 100 kg | ~ 9 040 lbs |

| Hydraulic unit | ||

| Nominal pressure: | 300 bar | ~ 4 350 psi |

| Oil tank filling: | 200 l | ~ 53 gal |

| Electrical system | 3NPE AC 50 Hz 230/400 V | 3NPE AC 60 Hz 275/480 V |

| Main motor: | 7,5 kW | ~ 10 HP |

| Cooling unit: | 0,75 kW | ~ 1 HP |

| Heating coil: | 1,5 kW | ~ 2 HP |

HSB 1200 series

| metric units | imperial units | |

| Tool length (T): | 1 250 mm | ~ 49 ¹/₄" |

| Stroke (S): | 280 mm | ~ 11" |

| Splitting power: | 63 / 80 tons | ~ 69 / 88 US tons |

| Quantity of splitting teeth: | 25 + 25 (with 50 mm) pcs | 25 + 25 (with 2") pcs |

| Main dimensions | ||

| Width (W): | 2 320 mm | ~ 7ʹ 7 ¹/₃" |

| Width - side tools extended (SW): | 3 640 mm | ~ 11ʹ 11 ¹/₃" |

| Length (L): | 960 mm | ~ 3ʹ 1 ³/₄" |

| Height (H): | 3 575 mm | ~ 11ʹ 8 ³/₄" |

| Weight (without oil filling): | ~ 6 250 kg | ~ 7 170 lbs |

| Hydraulic unit | ||

| Nominal pressure: | 300 bar | ~ 4 350 psi |

| Oil tank filling: | 700 l | ~ 185 gal |

| Electrical system | 3NPE AC 50 Hz 230/400 V | 3NPE AC 60 Hz 275/480 V |

| Main motor: | 23 kW | ~ 31 HP |

| Cooling unit: | 0,75 kW | ~ 1 HP |

| Heating coil: | 1,5 kW | ~ 2 HP |

Models